Sausage Clipping

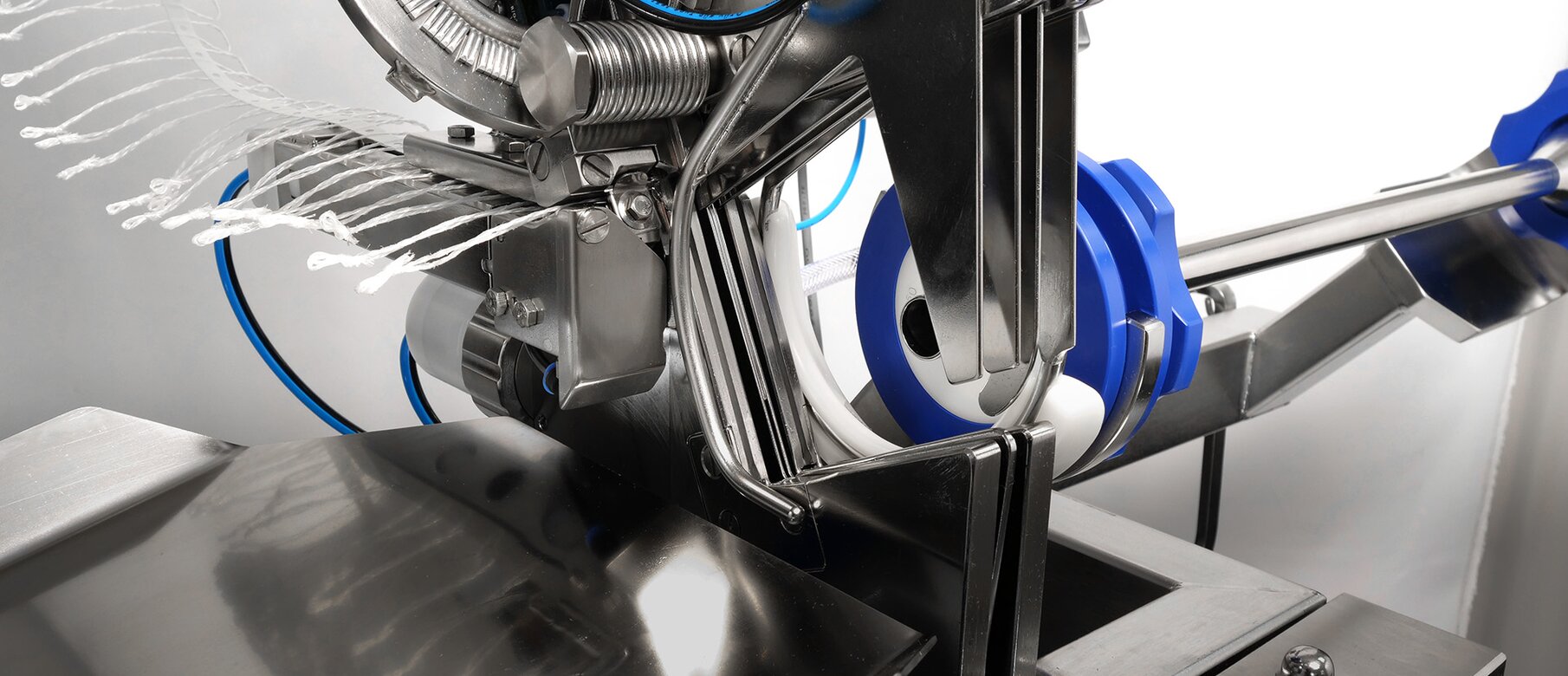

The right sausage clipper for every application – from portioned sausages to sliced products.

Our sausage clippers help make your production more efficient, more hygienic, and faster – your processes remain precisely calculable. These versatile machines are suitable for clipping sausages and meat products, various types of packaging, and plant-based alternatives.

WHY SAUSAGE CLIPPERS ARE INDISPENSABLE IN PRODUCTION

CLIP SYSTEMS sausage clippers enable fast, secure closure of sausage casings and packaging in a wide range of materials and sizes. Process reliability and consistent product quality are significantly increased – even at high cycle rates. Leaks and contamination risks are reliably minimized. Compared to knotting, tying or thermal sealing, the clip closure offers greater precision, flexibility and cost-effectiveness. The devices from BECK CLIP SYSTEMS ensure a tear-proof seal and can be easily integrated into existing lines. Short changeover times and a low-contact process support the highest hygiene standards.

Advantages of clip closure

-

Automation potential

CLIP SYSTEMS sausage clippers from BECK enable largely automated processing – for less manual intervention, stable processes and high line output.

-

High process reliability

The automated clip closure ensures high process reliability and consistent quality – leaks and contamination are reliably avoided and your production can be reliably planned with BECK CLIP SYSTEMS solutions.

-

Time and cost savings

The low-contact clipping process enables hygienic production at the highest level.

With sausage clippers from BECK CLIP SYSTEMS, even the strict hygiene standards of the food industry can be met with ease. -

Hygienic processing

The low-contact clipping process enables hygienic processing at the highest level: the strict requirements of the food industry can be easily met with sausage clippers from BECK CLIP SYSTEMS.

TECHNICAL REQUIREMENTS & SOLUTIONS

What modern clippers have to achieve – and how BECK CLIP SYSTEMS meets these requirements. Reliability, speed and versatility are what count in sausage production. CLIP SYSTEMS products from BECK are designed precisely to meet these requirements – for professional use in craft and industrial businesses, whether sensitive natural casing or robust artificial casing – our clippers seal securely and gently. This means: no tearing, no leaks – but consistently tight seals with every batch.

Thanks to flexibly adjustable clip diameters, a wide range of calibers and product shapes can be processed effortlessly. Precision remains constant even at high cycle rates – for efficient processes in continuous operation. Our machines can also be easily integrated into existing lines – from filling technology to portioning and packaging.

Maximum precision, maximum efficiency – our CLIP SYSTEMS sausage clippers and systems from BECK master every challenge of industrial food production.

All sausage clippers from BECK CLIP SYSTEMS offer intelligent and versatile solutions that can be easily adapted to different casing types, packaging formats, and production conditions. Their robust construction and well-engineered mechanics ensure consistently high performance – even under continuous operation. The machines are compatible with a variety of line components and can be seamlessly integrated into automated processes – ensuring reliable workflows, high cycle rates, and maximum product safety.

As a family-owned company with over 120 years of experience, we support you with technical expertise and personalized service – reliable, fast, and solution-oriented.

Recommended Sausage Clippers & Clipping Machines

Perfect clippers for sausage products

The new BCS-SC series is easy to use, compact, and reliable – ideal for daily use in small-scale operations or businesses with lower output. The machines are quick to set up, pleasantly lightweight, and enable clean, safe operation. Thanks to the stainless steel-coated cylinder, they are durable, easy to clean, and low-maintenance. The design meets strict hygiene standards – a clear advantage when processing unpackaged food products.With the BCS-SC series, you can securely seal a wide variety of sausage products – such as scalded sausages, cooked sausages, portioned sausages, spreadable sausages in synthetic casings, or snack items in pouches. This system is particularly well-suited for products that require sealing on only one end – for example, continuous casings or bag-style packaging.

The new BCS-SC tabletop single clippers are easy to set up, lightweight, and reliable. Thanks to their innovative design and stainless steel-coated cylinder, the machines are highly ergonomic, low-maintenance, and easy to clean. The new construction also ensures compliance with the highest hygiene standards.

The swing-open tabletop double clipper BCS-200DC-R is a particularly robust machine for sealing synthetic and natural casings in the 25 to 100 mm caliber range. The clipper is easy to operate, space-saving, and quickly ready for use thanks to its swing mechanism. This makes it especially well-suited for producing ring-shaped sausages and for packaging in nets.

The semi-automatic double clipper BCS-700SMD features an integrated touch control panel and can be mechanically connected to any filling machine. It is particularly well-suited for clipping sausage products in the 30 to 140 mm caliber range.

The fully automatic CLIP SYSTEMS double clipper BCS-700AM can be mechanically connected to any filling machine. An integrated control unit on the clipper synchronizes operation with the filler, which ensures precise portioning by weight. This automatic clipper is ideal for sealing all types of casings in the 30 to 140 mm caliber range – making it a perfect solution for production facilities of all sizes.

Perfect clippers for sausage products

FAQ | sausage clippers by beck clip systems

Single clippers from BECK CLIP SYSTEMS apply a single aluminum clip to securely seal a product. They are ideal for small to medium production volumes, such as sealing bags or casings on one end. Double clippers operate automatically and apply two clips in one step: one at the end of the finished product and the next one for the following unit. The casing is cleanly cut between the two clips, creating a continuous production chain. This solution is especially suitable for high-speed, continuous industrial use while maintaining consistent quality.

The right clip by BECK CLIP SYSTEMS depends primarily on the diameter of your product, the casing type (e.g., natural or synthetic), the filling material, and the desired sealing strength.

As a general rule:

For smaller products like mini sausages, portion sausages or snacks, narrower clips with a small opening angle are used.

For classic scalded or cooked sausages in medium calibers, proven standard clips are recommended – providing a tight seal without damaging the casing.

For large calibers such as salamis, raw sausage sticks, or moldable sausages, stronger clips with high closing force are needed – ensuring safe sealing even with firm fillings and heavier weights.

Our aluminum clips are available in various hardness levels, sizes, and materials. For quick and accurate selection, the digital BECK ALUMINIUM CLIPS CLIP FINDER considers all relevant product and machine parameters.

Our clip closure technology is specially developed for use in food processing – even in sensitive production environments. The clips are made of food-grade aluminum, precisely manufactured, and strictly quality controlled. The devices are made of robust stainless steel with smooth surfaces and are designed to prevent dirt build-up – making them easy to clean and ideal for maintaining high hygiene standards in daily operations. The result: a secure, airtight clip closure that seals the product reliably, prevents contamination, and extends shelf life – all without the need for additional films or adhesives.